- Tips and tricks using mastercam x5 generator#

- Tips and tricks using mastercam x5 full#

- Tips and tricks using mastercam x5 software#

- Tips and tricks using mastercam x5 code#

SOLIDWORKS CAM uses a free Universal Post Generator and also provides many free posts, but the provided free posts are not easily customizable by the end user and not all machines are supported. Mastercam posts are quick and easy to customize.

Tips and tricks using mastercam x5 code#

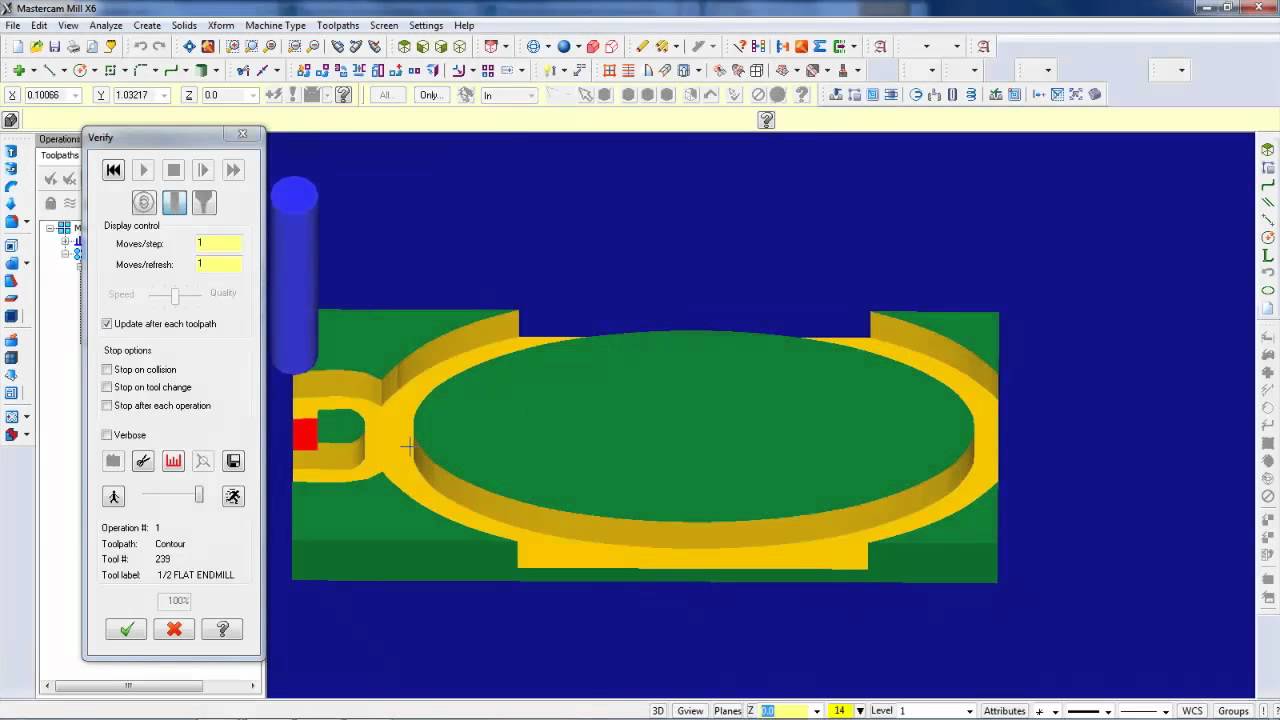

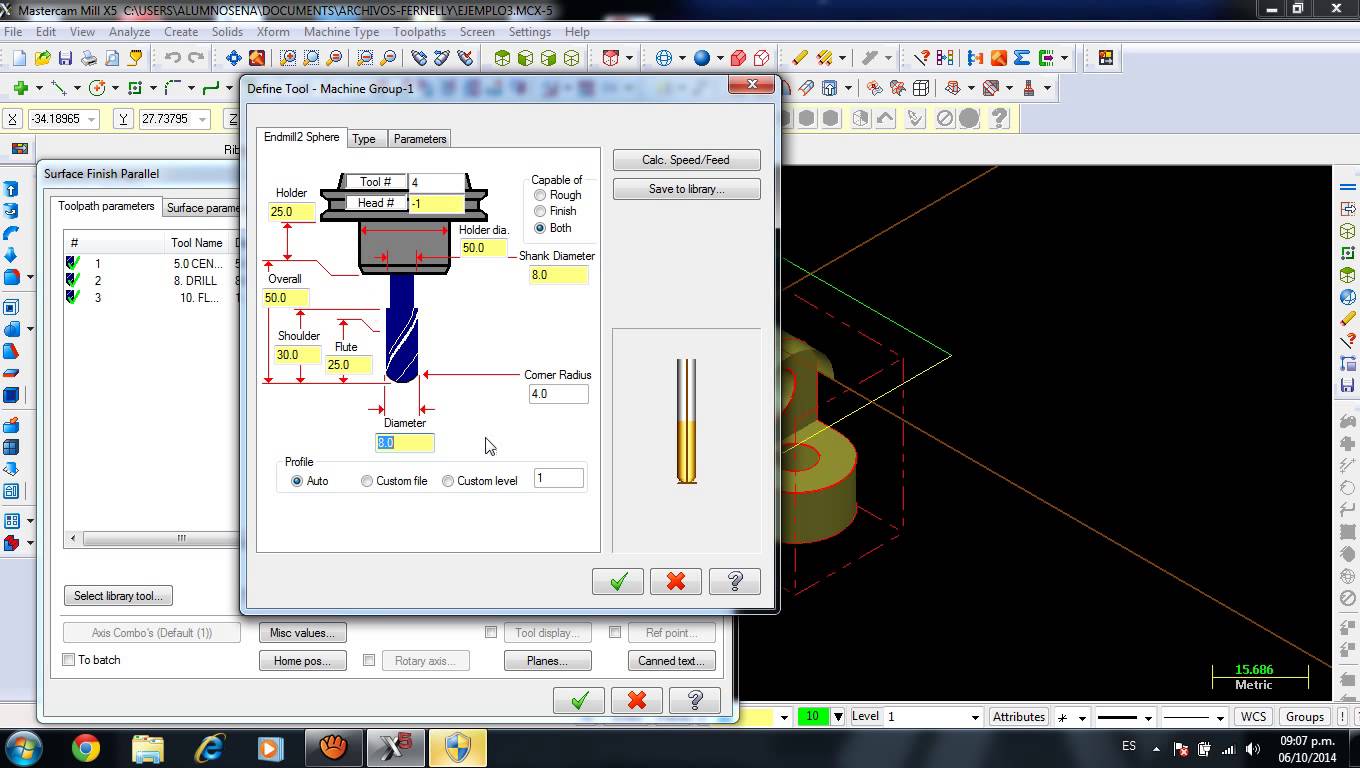

Both tools can generate accurate toolpaths, are flexible to setup and configure the specifics of the toolpath options and can output NC code for your machine.Many advanced features in SOLIDWORKS require additional processing of this bad data before it can be used.

Tips and tricks using mastercam x5 software#

You can often skip many steps using CAM software because it can achieve the correct toolpath easily with simple curves or surfaces applied to a simplified model.

Previous SOLIDWORKS or parametric CAD users will find using the Mastercam Design to be frustrating to use beyond small design changes and edits. Anyone with any CAD experience will find SOLIDWORKS easy to pick up and use. SOLIDWORKS is everywhere and is easy to learn.If your primary function is design and model creation you can’t do better than SOLIDWORKS. It makes quick work of generating the exact model geometry you need, and parametric geometry makes quick work of design changes. The SOLIDWORKS User Interface is highly optimized for modeling, with slick contextual menus and intelligent sketch snapping and dimensioning.These tools don’t typically compete on features unless you happen to fall right in the sweet spot between their respective primary capabilities. Keep in mind, these are two very different tools that are considered the leader’s in their respective markets. So, let’s compare the two programs to see how they stack up on a variety of topics.

Tips and tricks using mastercam x5 full#

So, when do you use one or the other and do you need to buy both? The easiest way to describe which tool you should primarily use is to ask yourself if you are a “designer who also needs to program some parts”, or if you are a “machinist who is modeling parts to program them”? However, even that fails to capture the question in full and how it might impact your daily work. Both can create model geometry, both can generate NC code, and both have additional unique capabilities that might make it a compelling choice for you. I often get questions related to using Mastercam or SOLIDWORKS for a given task because they overlap in a lot of what they do and not everyone can learn or even afford to buy both tools right away.

0 kommentar(er)

0 kommentar(er)